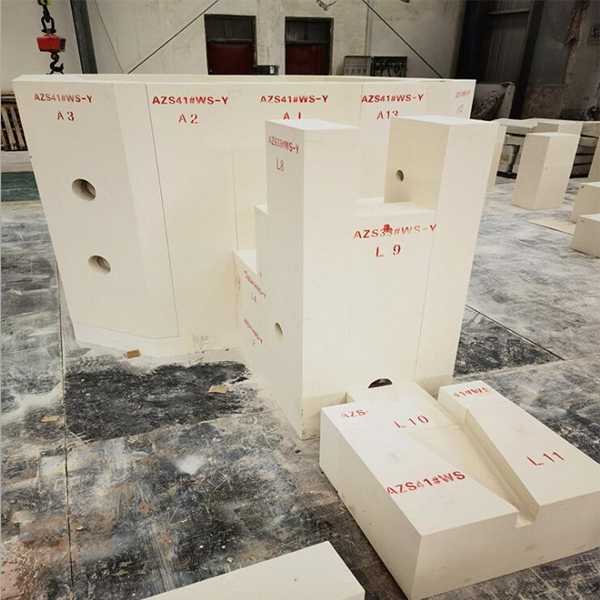

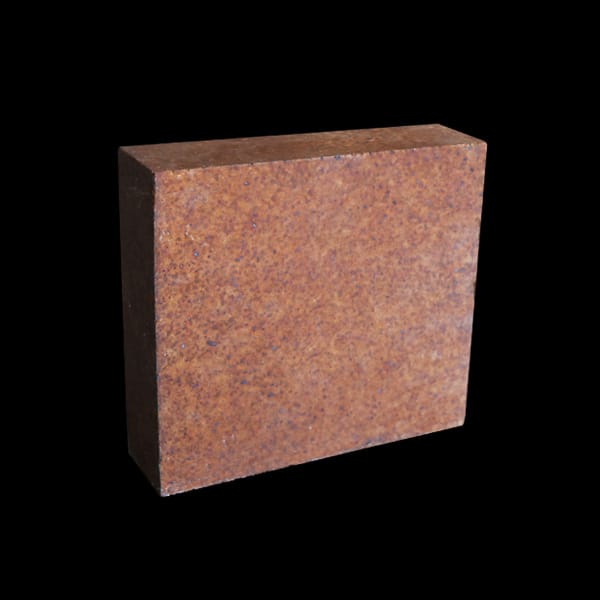

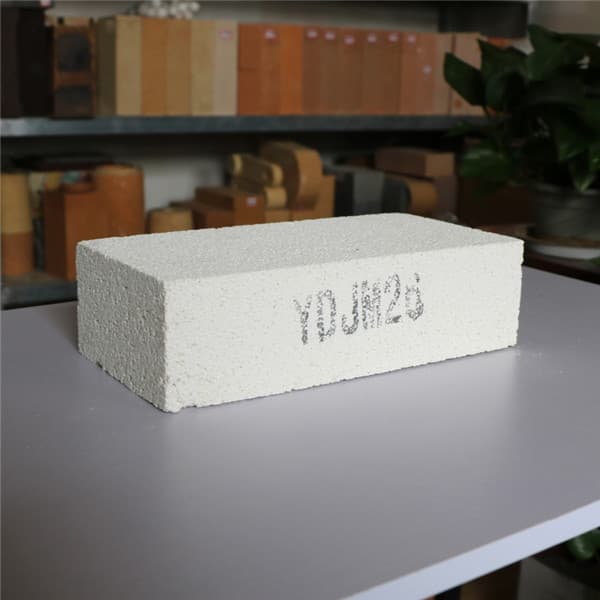

Refractory Material Products

Our advantage refractory for you

Refractory manufacturer, optimal solutions for you.

Our Client

All over the world

About Us

Yuhua Refractory was founded in 2006, located in Chaohua Industrial Area, Xinmi City, Henan Province, P. R. China. We are a comprehensive modern enterprise integrating production & research, design, product technical solutions and the general contracting and operation of refractory materials.

Email: info@ht-refractory.com

Mob/WhatsApp/Wechat/Skype: +86 18768897129

Why Choose Us?

Service

Solution

We provides one-to-one solutions by your inquiry.

Manufacturer

True refractory manufacturer, provide OEM/ODM.

Standardization

Create value for you through standard quality management.

Factory price

Relying on the strict control of production, we can give you competitive price.

ISO9001

As ISO9001 ensuring high quality and continuous improvement of process and product quality.

Shipping

Through years of precipitation, we can ship to you with lower freight, no matter where you are.

Case&News

Know Yuhua every day

-

03

2022-12

Factors causing damage of refractory bricks1、 Chemical factors1.1)Chemical erosion of molten slag (including chemical erosion of melting furnace dust).It is generally the main factor for the corrosion of refractory brick lining in smelting furnace.2)Chemical attack of furnace ga··· ...

-

03

2022-12

Refractory brick is refractory brick. It is an inorganic metal material at 1580℃. It is the basic material of service technology. It is the structural material of thermal equipment such as masonry furnaces. It is also used to manufacture containers and components of a certain le··· ...

-

10

2022-06

What is the main purpose of magnesia bricks? Magnesia bricks are rarely used by us. It is different from ordinary building bricks. Magnesia bricks have very good fire resistance properties. In addition to being used as building bricks, there are other uses. Then What are the prop··· ...

Wechat Us

Wechat Us